Why are pull-testers used in roofing and construction ?

This purpose of this article is to inform you why pull testers are used with particular reference to their use in the construction industry and to provide relevant links.

As their name suggests, pull testers are used to carry out pull tests.

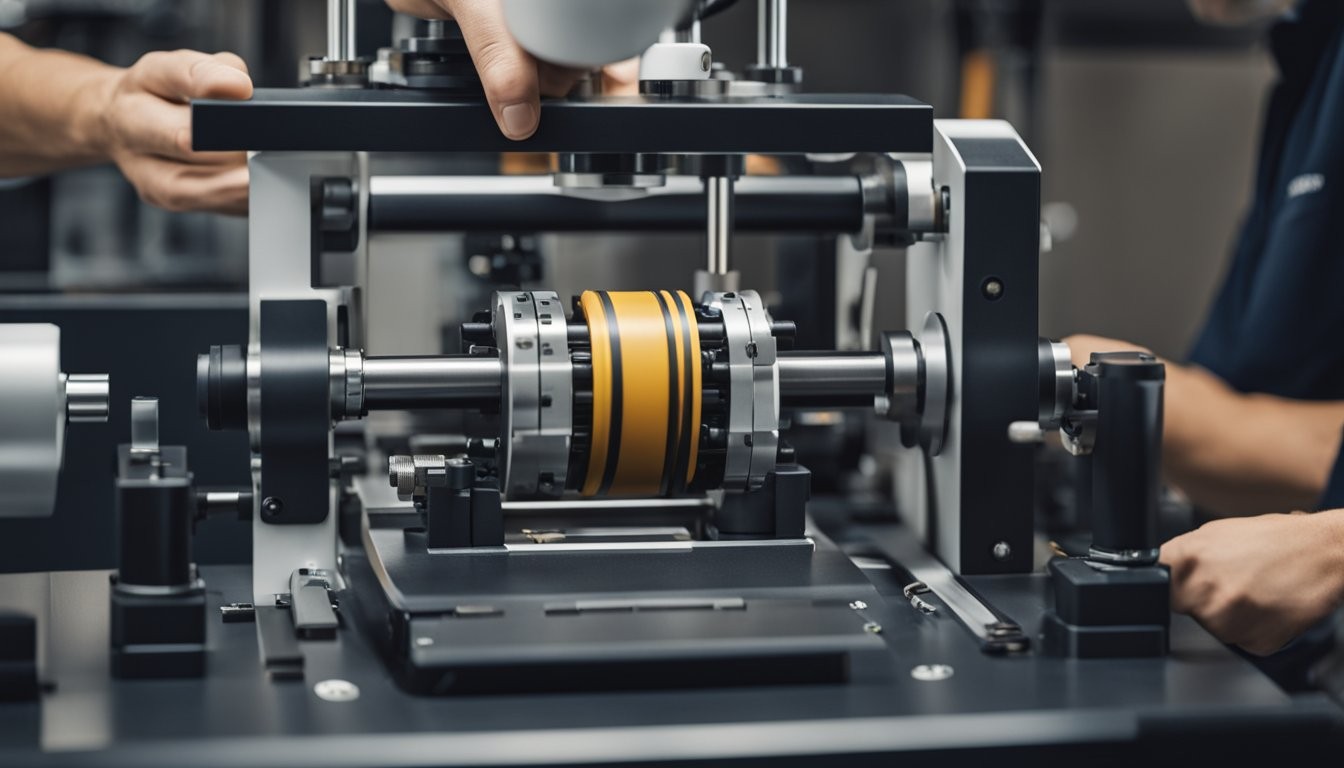

They are portable digital or analog force gauges and measurement devices used across a variety of industries to help assess and ensure product quality.

Why are pull testers used in the Construction Industry?

In construction, pull tests can be carried out to ensure meet construction work meets certain code or standards, including national code, model code (including American Standard Test ASTM standards), local code or Eurocode requirements or just as ‘good practice.’ The need for them has largely come about as wind forces can cause considerable damage to building and infrastructure.

The decision to use a pull tester is primarily made for situations where building code resistance states or implies that mechanical resistance is the issue.

Pull-tests may be necessary to demonstrate construction work meets current construction codes such as the 2012 International Building Code (IBC), 2012 Residential Building Code (IRC), Occupational Safety and Health Administration (OSHA) 1926 standards, American Standard Test Methods (ASTM) and American National Standards Institute (ANSI) standards. In hurricane exposed areas such as Florida, the Florida Building Code Testing Application Standard (TAS) is applicable.

Every detail should be checked with pull testers to ensure structures hold under both normal and any possible abnormal conditions such as hurricanes and earthquakes.

They are portable devices that can be used in the field. They are suitable tools for testing the mechanical resistance of general construction elements, roofing assemblies, safety equipment and insulation.

Mechanical Testing

Various kinds of mechanical tests are required to confirm material properties are reliable, within design limits, safe and securely fixed.

These include:

- Pull out force test

- Breaking force test

- Withdraw force test

- Extraction force test

- Bond test

- Adhesion tests

- Foam compression test

- Static load tests on fixtures

Pull tester users may have to provide test certificates to an authority or to a manufacturer to cover liability, conform with government regulations, codes and standards and to meet quality standards.

Some examples of construction codes and standards relating to the use of pull testers include the following:

TAS 124

Florida Building Code’s TAS 124-95 is a procedure for testing field uplift resistance of existing membrane roof systems and in situ testing for reroof and new construction applications.

ASTM E2359

ASTM E2359 is the US national standard test method for field pull testing of in-place Exterior Insulation and Finish System (EIFS) wall cladding assemblies. It is the most valuable method for determining the resistance of a section of them.

Pull Test Certification : using a Com-Ten pull tester is using a benchmark tool

Every pull tester is calibrated and delivered with a calibration certificate to show their high benchmark level of reliability.

There is a large variety of testing solutions, pull testers and accessories available for the construction industry for general construction, roofing, safety, insulation purposes.

Motorized pull tester versions are also available.

Com-Ten pull-testers presents the construction industry with a large variety of solutions with all the relevant accessories to meet code and standard requirements.

For more information on the different pull testers Com-Ten offers for your applications, please refer to the Com-Ten category sections: